Q&A

In one of our previous columns, we looked at the hardware revolution that is transforming the business and technology landscape. One of the most interesting and fastest-growing areas starting to hit more mainstream businesses is 3D printing.

Q. What is 3D printing?

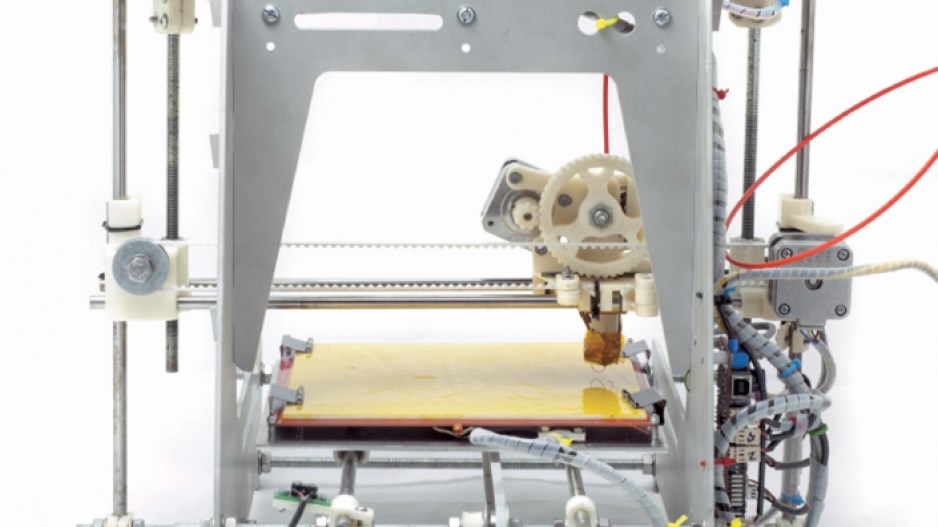

A. 3D printing involves making a three-dimensional object from a 3D model or other electronic data source. This is done primarily through what are called additive processes in which successive layers or material is laid down under computer control. It is not a new technology – its roots go back to 1984, when Chuck Hull of 3D Systems Corp. invented a process known as stereolithography employing UV lasers to cure photopolymers. In 1990, the plastic extrusion technology was commercialized by Stratasys, and in 2005 it took off with hobbyists with the open-source RepRap project where a 3D printer could be used to build parts for more 3D printers.

Q. What’s the big deal?

A. 3D printing technologies are disrupting many industries and redefining the supply chain. You may have seen in the news how 3D printers are transforming a number of sectors such as construction, in which companies in China and Europe have used 3D printing approaches to “print” entire concrete houses. Another exciting area is the biomedical field, where researchers are printing replacement lungs using additive processes. There are 3D printers that print chocolate, candy and other foods, and there are 3D printers that can use metals to create jewelry. Businesses are finding that instead of ordering expensive parts and having to wait long periods for shipping, they can instead just download a part or design a custom part and print it immediately using a 3D printer, or outsource to a local 3D printing service.

Q: How can getting a 3D printer benefit my business? Isn’t it just a hobbyist fad?

A: While there is a sizable hobbyist segment, 3D printing is starting to go mainstream as companies realize they can save time and money by printing parts or other objects locally right in their business rather than having to source from across the world. Even more valuable is the ability to inexpensively produce prototypes. This year some key 3D printing technology patents, related to a technology called laser sintering, expired. This is expected to prompt a big drop in pricing for higher-end 3D printers.

Q: Where can I go to learn more?

A: There is some excellent 3D printing talent and experience right here in the Lower Mainland. One of the leading groups is called 3D604.org. It has regular meet-ups and an active online forum. The group’s co-founder, John Biehler (www.johnbiehler.com), and another local guru, Bill Fane, co-authored a book, 3D Printing with Autodesk.

Q. How much will it cost?

A. According to Don Read, owner of 3Design Products Inc., there are three main price ranges. The first is the under-$5,000 range, and most 3D printers in this group are for home hobbyists. Most of these printers use a fused deposition modelling approach, in which material is melted and extruded in layers. The second price point is $5,000 to $100,000 and is mainly for businesses. Many machines in this price range use selective laser sintering, in which a bed of powder material is “sintered,” or hardened, layer by layer, and then the model is pulled out of it. Then there are 3D printers costing $100,000 or more that use a variety of technologies to produce 3D objects with speciality materials, including metals such as titanium alloys.

Q. Where can I buy a 3D printer?

A. Many people in the Lower Mainland buy their 3D printers online. For example, if you want a popular Makerbot 3D printer, the leading distributor in Western Canada is Thor3D (www.thor3d.ca). There are some great local places, though, where you can also take a look at some 3D printers and take one home with you. One exciting local company that is making it big on the international stage is Vancouver-based Tinkerine (www.tinkerine.com). Check out its Ditto Pro, Ditto+ and Litto 3D printers, which range from about $1,100 to just under $2,000. Less expensive models come as DIY kits.

Another leading local 3D printer distributor is 3Design Products (www.3designproducts.ca), where you can get high-end, industrial ZPrinters and the popular CubeX printers. The company’s website has a number of helpful 3D printing resources for businesses.

If you would like to see different types of 3D printers and learn about selecting and buying a 3D printer, there is a Makers Monday meeting that offers regular workshops (www.meetup.com/North-Vancouver-Makers-Meetup).

Q. Where can I learn more?

A. One of the best resources to help you pick a 3D printer right for you is Make magazine’s Ultimate Guide to 3D Printing 2014 (makezine.com/volume/guide-to-3D-printing-2014). It provides detailed reviews of dozens of 3D printers.

Q. If I don’t want to buy my own 3D printer, where can I get my 3D models printed?

A. There are a number of 3D printing services online, such as Vancouver-based Key3D (www.key3d.com), where you can just upload your file and the service provider will ship you your finished 3D object. There is even an innovative service, 3D Hubs (www.3dhubs.com) where you can locate the closest local 3D printer, submit your design and then pick up nearby, usually a short time later.

3D printing is going to have a big impact on business. It’s worth looking into. •