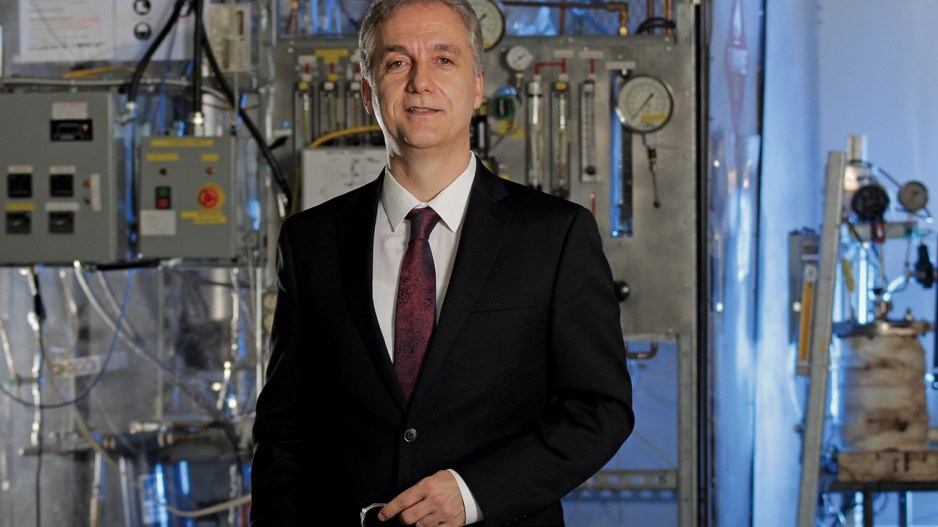

Goran Vlajnic, executive director of the Vancouver-based Carbon Capture and Conversion Institute (CCCI), knows there’s a political cloud hanging over the scientific advancements he’s working on.

With the shift in government in the United States – the world’s second-largest carbon emitter – and the election of Donald Trump, the issue of human-caused global warming has been lent even greater urgency.

Vlajnic, a former development engineer for Devon Energy, where he worked on a molten carbonate fuel cell for carbon capture, is on the front lines of the fight to reduce carbon dioxide (CO2) in industrial emissions. He also said he embraces the challenge of the underlying goal: making carbon capture technology affordable and effective enough that companies will want to use it all over the world.

“I think it’s wrong to have this issue so politicized; it’s not helping anybody,” Vlajnic said. “The current situation and the government in the United States – they can accept or deny it – it’s something that is going to be, I hope, only around for the short term.”

The CCCI is a non-profit collaborative venture between CMC Research Institutes and BC Research Inc. that has been tapped to develop the means of potentially combining two technologies to reduce carbon emissions by industrial companies. This includes liquefied natural gas facilities and cement plants, both of which emit large quantities of C02. According to a release from the CCCI, industrial CO2 accounts for 46% of global greenhouse gas emissions.

Based in downtown Vancouver, Vlajnic and the CCCI are now working with U.S.-based Westec Environmental Solutions and SINTEF, Norway’s largest independent scientific research organization. Westec has created a unique contactor container, also known as a scrubber column, in which CO2 is captured by a solvent, and SINTEF has developed a new precipitating solvent.

Initial testing is being bankrolled with $3 million from CLIMIT, Norway’s national carbon capture and storage research funding program. If the two technologies can be integrated by the CCCI and scaled up, the combined process could reduce CO2 emissions for industrial companies using it.

Westec CEO Bill Hargrove explained how the technology might work. Exhaust from industrial burning of fossil fuels is pumped into a scrubber column that has a solvent that absorbs carbon dioxide. After the solvent exits the scrubber column it is sent to a regenerator where the CO2 is driven back out of the solvent by heating it up. Pure CO2 comes out of the regenerator and the solvent is sent back to the scrubber to capture more carbon. The pure CO2 that comes out of the regenerator is then cooled and compressed for reuse by industry or storage underground.

“The purpose of the [project] is to reduce the cost of the whole operation,” Hargrove said. “In order to drive off the CO2 in the regenerator, heat is required. The process requires large volumes of solvent. For example, a medium-sized fossil fuel power plant, say 500 megawatts, would require tens of thousands of litres per hour to operate. Heating all that solvent is a large factor in the cost of operation of the capture plant. The goal is to reduce that cost significantly.”

Vlajnic said a recent trip to China in which he was a delegate for a carbon capture technology forum shed new light on the issue for him.

“We went to Beijing and Shanghai and nobody there can deny it – that there is pollution there and there is a crisis.”

B.C.’s Ministry of Natural Gas Development is working on a regulatory policy framework for carbon capture and storage, noting on its website that the greatest potential for carbon capture storage emissions mitigation in the province is in the natural gas sector, due to the presence of large CO2 sources, including natural gas processing plants, near geological storage sites.•