A Burnaby company that developed a faster, cheaper way of capturing carbon dioxide from industrial processes is getting a $25 million boost from the Trudeau government.

The federal money, which comes from the government’s Net Zero Accelerator program, is intended to help Svante scale up commercial production. The company plans to invest nearly $100 million to expand its production facilities in Burnaby.

"To me, when you say let's build back better, what's one of the best examples?" Francois-Philippe Champagne, federal minister of Innovation, Science and Industry, said Wednesday..

"It's projects like Svante, where you're creating jobs, you're supporting the economy, but at the same time you're protecting the environment and even (producing) a new technology that we can export."

Svante, formerly known as Inventys, has emerged as a leader in carbon capture technology, having inked deals with large oil and gas companies in Canada and the U.S., as well as large cement manufacturers, like Lafarge.

The technology has particular promise in the emerging blue hydrogen production space.

Svante has raised US$195 million in private equity to date, most recently concluding a US$100 million series D raise. Early investors include Chrysalix Venture Capital.

The Canadian government's $25 million contribution will help the company go into commercial manufacturing. Its new manufacturing plant will create 53 new jobs, and will also provide co-op work placements for 124 students.

“Not only are we investing in this generation of workers, but we’re preparing the second generation of workers in one of the key sectors of our economy,” Champagne said at a press conference Wednesday.

Carbon capture and storage is a key tool in addressing climate change. Some industries, like cement production and the petroleum industry, are hard if not impossible to abate. CCS will be critical in helping those industries reduce or eliminate their CO2 emissions.

It will also be key in “blue” hydrogen production. When CCS is used in conjunction with hydrogen production from natural gas, it dramatically lowers the carbon intensity of the hydrogen produced.

CCS is one of the seven pathways for reducing greenhouse gases recommended by the International Panel on Climate Change, but it is an approach that has only recently begun to see an uptick in adoption on a large scale.

“Carbon capture utilization and storage will be one of the key tools in our tool box,” Champagne said. “We were talking about CCS almost like a decade ago, and now I’m pleased to see that things are moving up at great speed.”

Svante has already demonstrated its CCS technology at a Lafarge cement plant in Richmond and bitumen operation in Lloydminster, Saskatchewan.

The company has been inking deals with companies in the U.S. to build commercial scale CCS plants. Chevron (NYSE:CVX) has contracted Svante to supply its technology for a new CCS plant in California, for example.

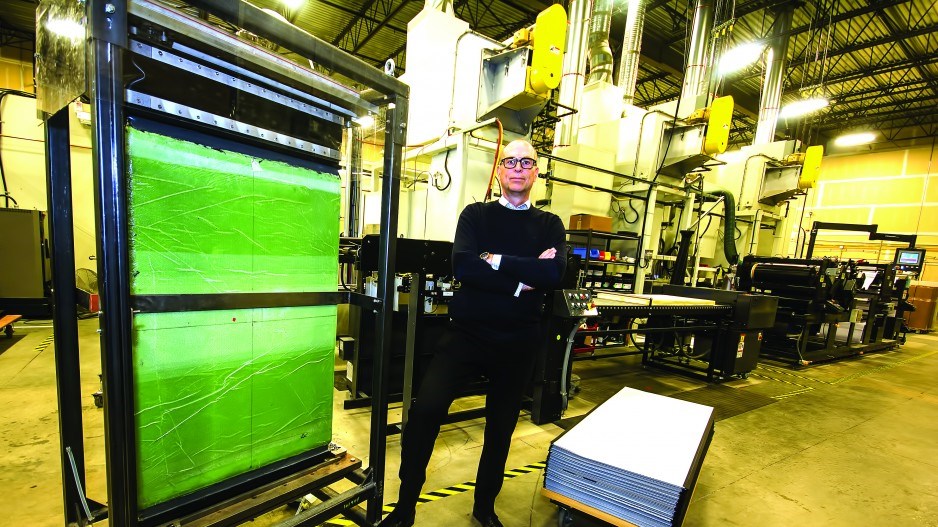

Svante developed a nano-material filter and a process that captures CO2 molecules coming from industrial processes, like steam methane reforming and cement production. One of the key breakthroughs in Svante’s technology is its speed. Its filters can capture and release CO2 within 60 seconds.

“Now we are looking to build a manufacturing facility that will be able to make these filters with that unique technology,” said Svante CEO Claude Letourneau. “With this $25 million investment, we are setting up a new centre of excellence for carbon capture use and storage in Vancouver.”

Letourneau said the new filter manufacturing plant will have a capacity to produce filters with 3 million tonnes of capacity per year. He said that means it would manufacture enough filters and modules to supply three plants, per year, equivalent to the Shell-Quest CCS plant in Fort Saskatchewan, Alberta, which captures 1 million tonnes of CO2 annually.

“So three of these plants a year – that’s the capacity we’re building up before we get a purchase order,” Letourneau said. “Right now, we are involved in several feasibility studies for commercial-scale plants ranging from about 500 to 4,500 tonnes per day capacity, primarily in North America but also in Europe."

In Canada, Letourneau said the two main industries expected to provide the biggest demand for CCS is cement production and blue hydrogen production.

As for incentives for industry, the federal government's carbon tax is the main market mechanism. In May, the federal government and cement industry, through the Cement Association of Canada, agreed to a strategy, the Roadmap to Net-Zero-Carbon Concrete, aimed at reducing the industry's emissions by 15 megatonnes by 2030 and 4 MT annually.