Sepro Mixing and Pumping, a B.C. industrial equipment maker, has won a $150,000 prize for technology that reduces the use of water at mine sites.

Foresight Canada and the Mining Association of BC (MABC) held a contest, the Mining Innovation Challenge, aimed at finding ways to reduce the use of water in mining operations. Mines use large amounts of fresh water to move mine waste (slurry), which must be stored in tailings ponds.

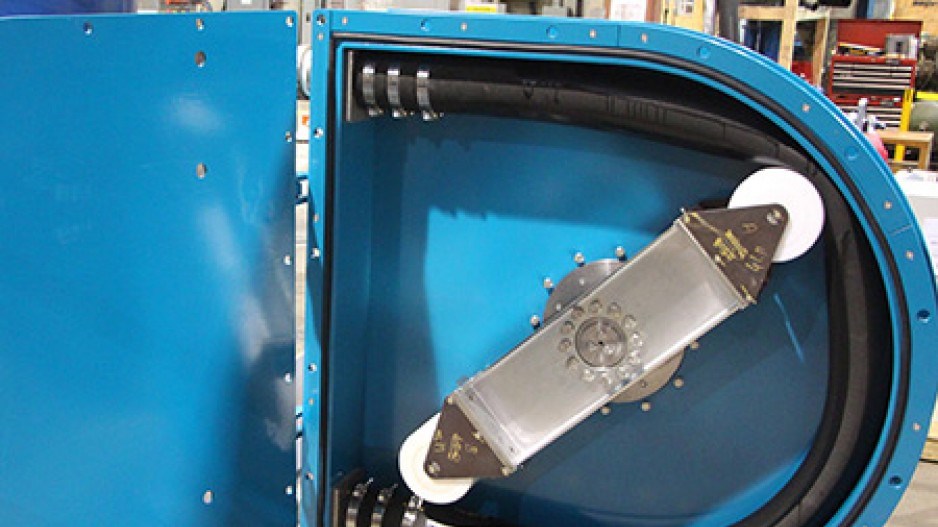

Sepro won the grand prize of $150,000 for its Large Scale Linear Fluid-Driven Peristaltic Pump.

"Their technology will limit water waste for slurry liquefaction and enable tailings to be delivered to a storage facility with much higher density than currently possible," Foresight and MABC say in a press release). "It will also allow water to be reclaimed for use at the concentrator and will enable more sustainable tailings storage techniques. Pilot opportunities are being explored for this technology."

“We believe we have achieved a breakthrough in peristaltic pumping that will substantially reduce the amount of water taken from the environment for mineral processing and allow construction of safer tailings storage facilities at lower cost than previously achievable,” said Sepro director Steve McAlister.

The prize comes with the potential to trial the technology in a pilot project at an operating mine.