A company in North Vancouver that provides small yet powerful components that help drive many clean technologies is one that Ottawa says will benefit from new tax credits.

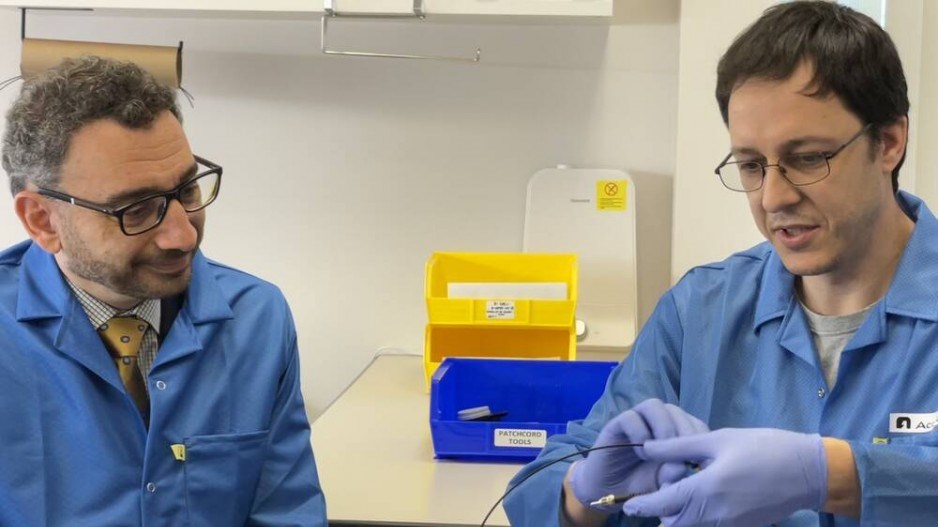

Federal Minister of Transport Omar Alghabra stopped by North Vancouver company Accelovant on Wednesday for a first-hand look at the home-grown technology.

The North Vancouver company uses a patented cutting-edge technology to make fibre-optic temperature sensors key to the efficient manufacture of semi-conductor computer chips.

Those chips are used in vast array of modern technologies, including green transportation options like e-bikes and electric vehicles.

“Last year’s cars have about 30 chips in each one. Electronic vehicles have 3,000 chips per vehicle,” said Accelovant Technologies CEO Michael Goldstein. Chips are key to safe fast-charging of electric batteries in everything from cell phones to cars, he said.

And while the computer chips themselves aren’t new, Acceleovant’s technology has been changing the way those chips are manufactured.

Temperature is key to the process, said Goldstein. What Accelovant provides is a special type of fibre optic sensor that uses light to detect and control temperature more accurately, and under extreme conditions.

Goldstein said he and co-founder Ondrej Mercl started their company six years ago, sinking his retirement savings into the venture and hiring a group of forward-thinking scientists, engineers, physicists and electronics experts.

They spent three years experimenting, without success, said Goldstein. Then in year four, “We hit a breakthrough” that has resulted in worldwide commercial patents and exports into a $100 billion global market.

Today the North Vancouver company’s products support “the tidal wave” of clean tech activity, said Goldstein, including everything from machines that remove dangerous particles from mining smokestacks to powering data centres around the world.

Virtually every chip in the world is made on a machine that uses sensors produced by only two or three companies worldwide, said Goldstein. Accelovant is one of those.

“We’re of course the new kid in town and our growth is currently exponential thanks to the work of Canadian technology. We’re the global tech leader. Our sensors are used in situations that no other device can be used,” he said.

The growth of electrification is further firing the business.

Currently Accelovant employs less than 50 people ranging from technicians to engineers and software and firmware developers. All 20,000 units shipped annually are manufactured in the company’s North Vancouver location. It helps that the finished sensors are very small, he adds.

Alghabra said he’s excited to see a company like Accelovant succeeding.

“There’s a race to build the clean economies of the 21st century,” he said.

Tax credits highlighted in the recent federal budget include a 15 per cent tax credit for investments in non-emitting electricity generation systems, like wind, solar, hydro or nuclear systems and a 30 per cent tax credit for investments in new machinery and equipment used in clean technology manufacturing. There are also tax credits for hydrogen technology and for extracting and processing key minerals used in clean technology.

Goldstein said getting some help with the cost of items like expensive equipment that goes into his business is welcome. “It’s like putting wood on the fire,” he said.