The recent announcement that Canfor Corp. (TSX:CFP) plans to spend $200 million to modernize a sawmill in Houston, B.C. was a rare blip of good news in a chyron of otherwise unrelenting negative headlines for B.C.’s forest sector.

Forest fires, upheld softwood lumber duties, anti-logging protests, reductions in the annual allowable cut, sawmill and pulp mill closures, moratoria on logging old growth, and a flight of capital by forestry giants to other jurisdictions – mainly the U.S. – has been the norm in the daily news feed for the B.C. forestry sector for the last couple of years. This despite strong prices for softwood lumber in the U.S.

For B.C. loggers and lumber and pulp mill owners, the decline of B.C.'s forest economy is mainly due to a dwindling fibre supply and high operating costs.

A Mountain pine beetle infestation and wildfires – very likely exacerbated by climate change – took huge amounts of timber out of B.C.’s long-term timber supply.

More recently, in 2021, in response to anti-logging activism on Vancouver Island, the NDP government placed a logging moratorium on 2.6 million hectares of B.C.’s "most at-risk old-growth forests," which has further reduced the amount of timber available for harvesting.

Based on a survey of logging contractors, David Elstone, president of the Spar Tree Group, estimates 1,000 jobs may have been lost due to old growth deferrals in timber harvesting alone. That’s not counting any jobs lost as a result of sawmill or pulp mill closures or curtailments.

“To be fair, reductions in timber harvesting and lumber production are not entirely due to old growth policy and deferrals,” Elstone writes. “Other factors such as the now-past mountain pine beetle epidemic and ongoing wildfires have definitely contributed in part to these decreases.

“However, it is well accepted by industry that old growth deferrals have further challenged industry’s ability to seek out economically viable fibre in an already increasingly constrained fibre supply environment.”

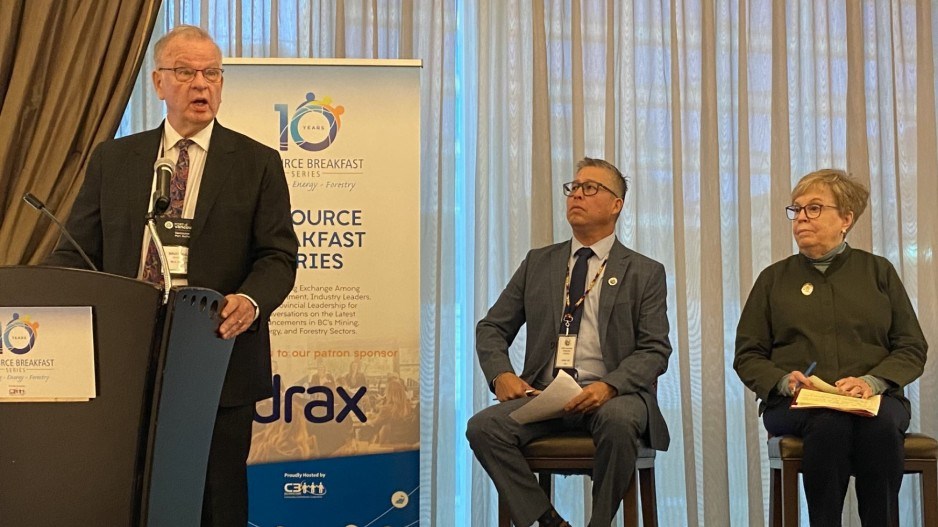

B.C.’s forest industry is necessarily undergoing a major transition from “high volume to high value” production, B.C. Forests Minister Bruce Ralston said at a resource ministers breakfast meeting Thursday.

One major change underway is the way planning is done for working forests. The B.C. government is moving towards a more holistic approach called forest landscape plans.

“They are designed to usher in a new way of managing the land base,” Ralston said. “We’ve updated laws and regulations to embed an eco-system health approach to forest decision-making. And we’ve created the silviculture innovation program to implement more alternatives to clear-cutting, such as selective harvesting, and many operators are already doing that.

“This new approach better manages ecological and cultural values by focusing on the entire forest eco-system – biodiversity, wildlife habitat, watershed health, forest resiliency and forestry. By focusing on forest health, we are also better able to withstand the threat of wildfires in years to come, while providing sustainable jobs for our forest sector.”

To incentivize higher value-added manufacturing, a dedicated fibre supply for small and medium-sized value-added manufacturers has been set aside within BC Timber Sales, and a $180 million BC Manufacturing Jobs Fund supports the retrofitting of “legacy” mills to higher value added products, Ralston said.

Forest landscape planning, which has been trialed in four regions, involve not just the forestry companies, but labour unions, community groups, First Nations, and local environmental groups, Ralston said.

“The vision is that there will be areas which will be economic zones, areas which will be no harvesting, areas where there will be a combination of both," he said.

In a case of making lemonade from the lemons, forestry companies are hoping to gain more access to fire damaged timber from forest fires.

Ralston acknowledged that there may be some economically recoverable fibre left over from forest fire that could be used in B.C. sawmills, pulp mills and pellet plants. He also acknowledged that fire-damaged timber has a “short half-life,” meaning that there is some urgency is getting permits to harvest it.

“I’ve heard concerns expressed by some communities and some companies that that process is not as fast as it could be,” Ralston said. “I’ve certainly made my views known on that.

“Certainly I’m confident that there will consideration on how to do that process and make that burned timber available for harvest.”