A $2.7 billion rebuild of Rio Tinto Alcan’s aluminum smelter in Kitimat would reduce much of the pollution the smelter currently produces, according to a new technical report obtained by Business in Vancouver.

The one exception is sulphur dioxide (SO2), which would increase from 27 tonnes per day to up to 42 tonnes per day – something that would aggravate pre-existing respiratory problems in people with asthma and bronchitis and increase acidity in soils and lakes in the area.

The report concludes the increased emissions could result in 150 to 200 additional incidents per year of restricted airways among people with asthma, bronchitis or emphysema.

That represents a 1% increase in breathing problems among those with pre-existing lung problems, according to one medical expert.

The report was done as part of the company’s application for a permit to increase SO2 emissions. The permit was granted April 24 but is subject to a 30-day appeal.

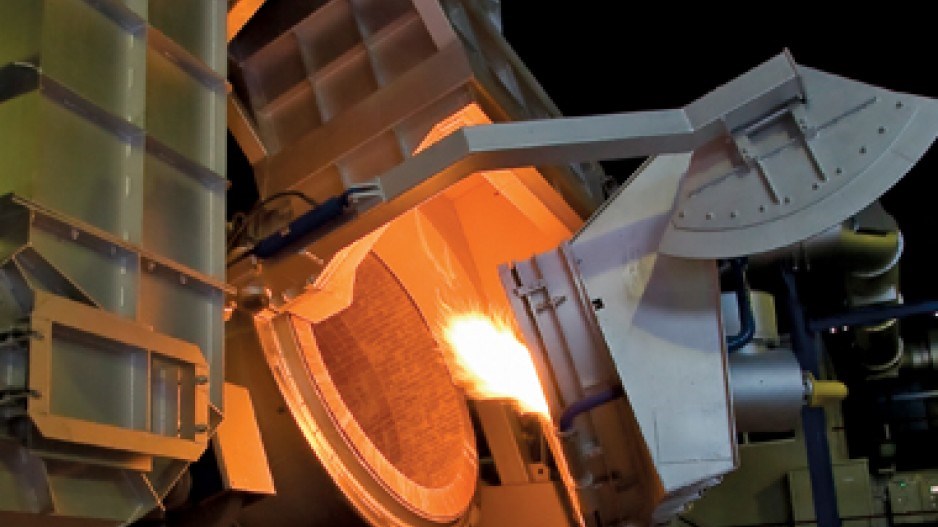

Built in the 1950s, Rio Tinto Alcan’s smelter in Kitimat is an open system, which allows harmful pollutants from the smelting process to escape, including fluorides, particulate matter and polycyclic aromatic hydrocarbons.

“It remains an open process,” said Douw Steyn, an air pollution expert at the University of BC’s Department of Earth, Ocean and Atmospheric Sciences. “That’s stone age. We burned open fires in the stone age – we learned to close them in our houses. We shouldn’t be doing that industrially.

“It’s wonderful that as part of the expansion they’re actually modernizing the technology to reduce emissions.”

However, he adds SO2 levels have been going down in Kitimat over the past decade, due in part to the closure of pulp mills there, and said it’s a step backwards to have them go back up again.

But the increased SO2 emissions appear to be a trade-off for a decrease in other, more harmful pollutants.

“In our new smelter, all the emissions are captured and all the emissions go through a scrubber,” said Kerry Moran, operations director for the Kitimat Modernization Project.

The scrubbers won’t filter out the SO2, however.

Unlike copper, iron or silver, aluminum is not extracted from ore by heating and melting it – it is extracted from alumina using electricity, and a key component in the process is carbon, used as an anode.

Aluminum smelters use petroleum coke – a sulphur-laden byproduct of oil refineries – to make the carbon anodes.

The expansion and upgrade will boost production of aluminum from 282,000 tonnes per year to 420,600 tonnes, which requires an increased consumption of petroleum coke – hence the increased SO2 emissions.