Technology developed in Richmond by Kemetco Research Inc. will be used in the first manganese mine in North America.

American Manganese Inc. (TSX-V:AMY) will use a low-energy recovery process developed by Kemetco to process low-grade ore at the Artillery Peak project in Arizona. It’s just one recent example of how B.C. clean-tech companies are literally cleaning up in the mining sector.

Soaring demand for metals, a subsequent mining boom and increasing environmental standards are creating significant business opportunities for local companies involved in mineral recovery and mine remediation.

“Mining has a huge potential right now,” said Kemetco president Norman Chow. “All those materials used for steel-making are hot commodities. A lot of low-grade mining deposits are now economical because of the high prices.”

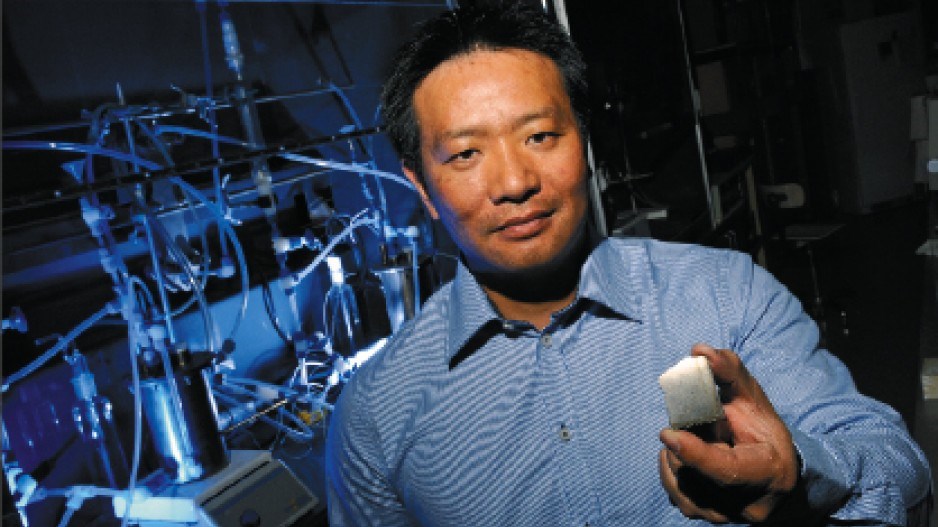

Kemetco is a private lab that specializes in chemical analysis and innovations for the oil and gas, chemical and mining industries, but it’s the latter where Kemetco’s biggest growth has been in the last couple of years.

Other local companies, like BioteQ Environmental Technologies (TSX:BQE) and Saltworks Technologies, are also benefitting from the demand for clean, low-energy approaches to cleaning up effluent and improving metal recovery from mining operations.

“We are pretty optimistic in terms of what we think is going to happen to this company over the next couple of years, and a lot of it is related to issues around environmental compliance,” said Jonathan Wilkinson, BioteQ’s new CEO.

Iron, metallurgical coal and manganese are used to make steel. Extracting those metals from ore is energy intensive, so in the past mining companies concentrated only on high-grade ore and left the lower-grade material in the ground or in tailings ponds, which is both a waste of a resource and an environmental liability.

“The tailings still has a lot of metal value but it’s more difficult to extract,” Chow said.

Kemetco has developed a low-energy process that makes it economically viable to extract manganese from low-grade ore.

“There’s no North American production of electrolytic manganese metal, mainly because all the manganese deposits in North America are low grade,” Chow said. “A lot of lower grade [metals] are economical now.”

Kemetco’s patented hydrometallurgical process for manganese recovery eliminates the need for roasting the ore and thus dramatically reduces energy costs. It uses chemicals rather than heat, and nanofiltration rather than evaporation to separate the manganese from the ore and clean up the water used in the process.

Kemetco’s patented hydrometallurgical process was tested in a $1 million pilot project in Surrey, and the results were published in the February 2012 issue of Metals and Metallurgical Processing magazine.

Kemetco has assigned the patent for its technology to American Manganese to be used in its Artillery Peak mine in Arizona, which would be the first manganese mine in North America. It is scheduled to start producing 140 tonnes of manganese per day in 2014.

Kemetco also has a contract with a large American corporation (Chow said he can’t disclose the company’s name) to build a $1 million pilot plant that will test its new acid-rock drainage process to be used in open-pit mines to recover waste metals and clean up tailings ponds.

“The water comes out clean, and you can recover the metals,” Chow said.

BioteQ also uses chemical and biochemical approaches in some of its processes. The company specializes in metals recovery and water treatment at mine sites and has sold 14 BioteQ plants in the U.S. and China, most of them in the copper-mining sector.

“While metals recovery continues to be important for us, we are really now looking for projects where there is an environmental reason for recovering and removing things like metals,” Wilkinson said.

“The benefit of extracting the metals and being able to sell them is that you essentially pay for an environmental project with the waste that you’re actually cleaning up.”

Saltworks co-founder Ben Sparrow said his company also expects to capitalize on the mining boom, but said stricter environmental regulations, not high metal prices, are the main driver for the demand. His company’s technology uses heat from the sun as well as ion exchange membranes to remove contaminants from brine, effluent and drainage from mines.

Canadian mining company Teck Resources Ltd. (TSX:TCK) has invested in Saltworks’ technology. •