Concern over Russia’s invasion of Ukraine is blanketing parts of B.C.’s tech community as questions linger over access to semiconductors chips.

Most of the world’s semiconductors are manufactured in Taiwan, but Ukraine and Russia are both major sources of the neon and palladium gases used in the manufacturing of these chips.

Russia’s invasion of its neighbour this week could further disrupt manufacturing of semiconductors amid ongoing supply chain disruptions that have made everything from new cars to PlayStation 5 consoles harder to come by.

“Supply chain disruptions and general business uncertainty – which always leads to hesitation to invest – are the main dangers, at least right now,” Jill Tipping, CEO of the B.C. Tech Association, told BIV.

“Semiconductor supply chains are already a mess and I agree this will make it worse.”

Wolf Richter, chief technology officer of Vancouver startup Epic Semiconductors Inc., said his company is “concerned” over the invasion and he’s hoping innovation will be able to overcome such a crisis.

“Silicon chip production is in the hands of only a few,” he said.

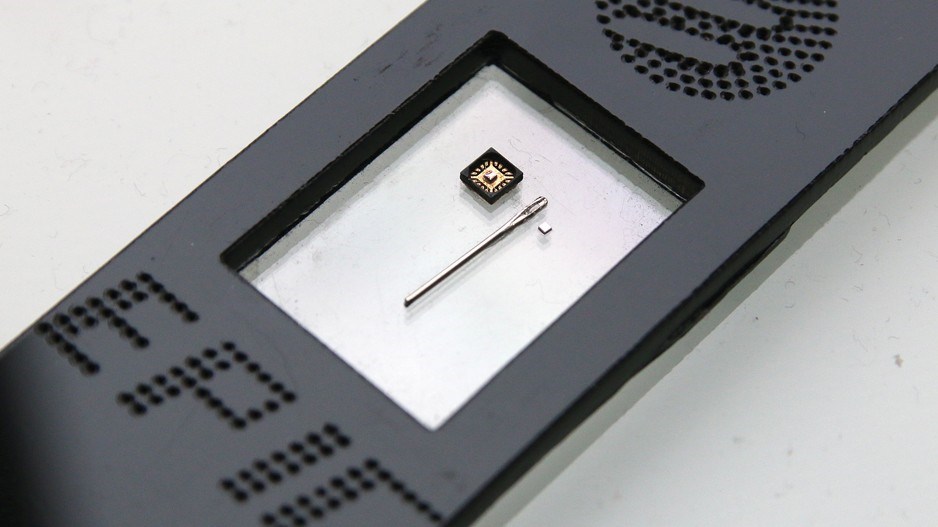

Epic’s technology – battery-free, microscopic AI chips known as “smart dust” – consume exponentially less energy and are exponentially smaller than standard semiconductors. Its chips function in much the same way as nerve cells and brain cells process electrochemical data, and they are less than a millimetre in size.

In the case of this B.C. company, manufacturing doesn’t rely on any third-party components, and the chips are produced using a variation of a laser printer tapping specialized ink.

Richter said the advent of such chips means printing these flexible electronics at home. It’s a prospect that would make businesses and markets less reliant on a small number of manufacturers and geopolitical uncertainty.

While most semiconductor manufacturing is done overseas, B.C. is also home to Redlen Technologies Inc., which specializes in manufacturing semiconductors used in medical imaging systems and baggage scanners.

The B.C.-founded firm was acquired last year by Japanese multinational Canon Inc. (TYO:7751) in a deal valuing the Vancouver Island tech company at just north of $400 million.

CEO Glenn Bindley said last year the acquisition would help his company source components more efficiently as Canon funds a $40-million plan to double its 50,000-square-foot manufacturing facility outside of downtown Victoria.

“I can tell you that supply lines are very stretched and that the Ukraine situation is very likely to have unintended consequences – likely ripple effect vs. direct,” he told BIV in an email Friday.

Bindley pointed to the fact that earlier this year a Japanese supplier for a critical, specialized circuit board would no longer be supporting Redlen after selling off all its capacity to a pair of tech giants for the next two years.

“The reason Apple and Samsung acquired the capacity was because a facility they were sourcing from in Taiwan was damaged in a fire. Supply is so stretched that there is no wiggle room and we became an unintended consequence of a fire in Taiwan,” he said.

Updated Friday, Feb. 25, with additional comments from Bindley